Manage Industrial Refrigeration Service

Run industrial refrigeration incidents, service visits, and maintenance in one live system so cold rooms stay online, technicians arrive prepared, and margins stay protected.

Run industrial refrigeration incidents, service visits, and maintenance in one live system so cold rooms stay online, technicians arrive prepared, and margins stay protected.

You handle alarms, emergency calls, and planned maintenance across many sites. Planfix keeps every incident, asset, visit, and cost in one configurable workspace so dispatch, technicians, and account managers share the same truth in real time.

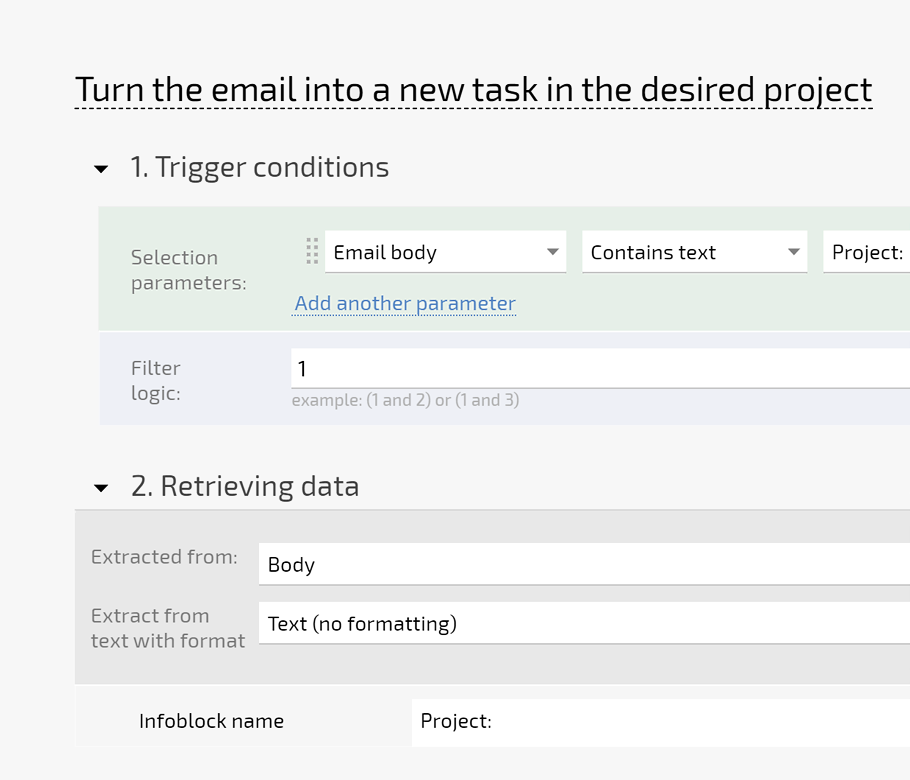

You do not need to redesign your service model today. Start by routing alarms, emails, and calls into Planfix as tasks, then use conditional lists so moving a card updates assignee, priority, or SLA without extra work.

You run an industrial refrigeration service team or manage outsourced maintenance across many sites. You juggle alarms, urgent calls, and preventive work yet still want fewer emergencies, cleaner audits, and calmer peak seasons.

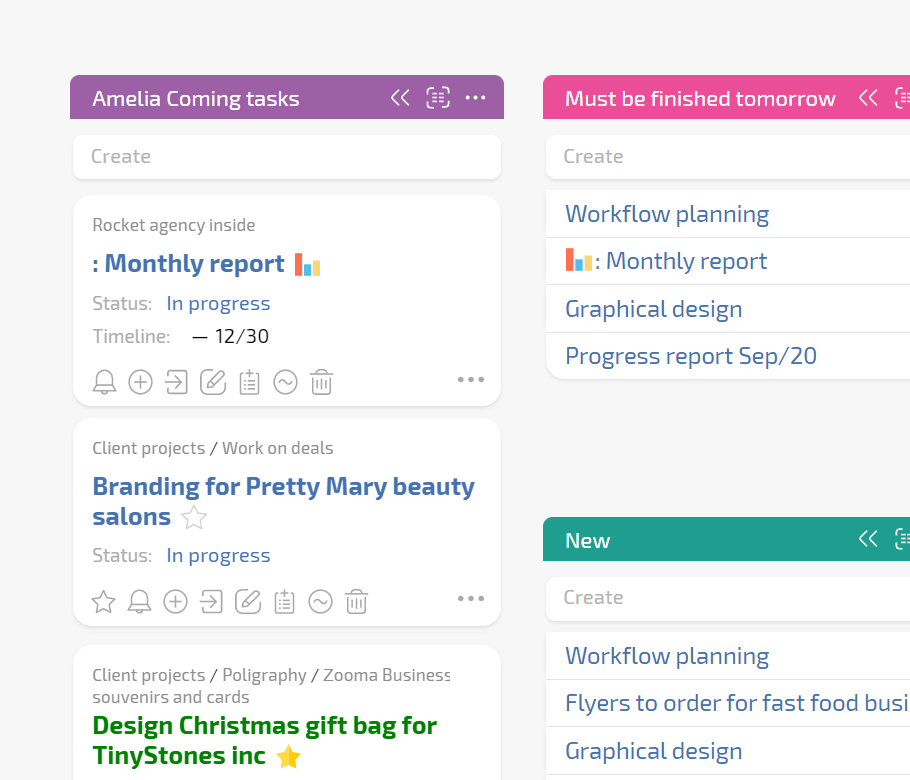

Show dispatch one Planner board where every open incident, visit, and follow up is sorted by SLA and region. Show clients a simple dashboard that lists their sites, open issues, and completed visits in real time without extra portals or spreadsheets.

You run a refrigeration service operation that is predictable, defensible, and profitable. You know what is happening on each site, who is working on it, and what it costs so you can steer contracts with confidence.

You may worry about scattered data, adoption in the field, or control and compliance. Planfix lets you start small, keep technicians focused, and give management a clean audit trail as you grow coverage step by step.

Planfix replaces scattered spreadsheets, generic ticketing tools, and rigid vertical systems. You get conditional boards, tasks on a map, data tags, and Project Totals in one platform so you can run true field service, not just log tickets.

Connect phones, calendars, storage, and messaging so incidents and site visits stay in one system.