Streamline Plant MRO Requests

Run every plant repair request, inspection round finding, and CAPA in one governed workspace. Planfix captures the signal, routes it to the right maintenance stream, and proves what was done.

Run every plant repair request, inspection round finding, and CAPA in one governed workspace. Planfix captures the signal, routes it to the right maintenance stream, and proves what was done.

Send operator reports, inspection rounds, and audit nonconformances into the right flow the first time. Keep asset, line, location, severity, and production impact in one record with separate lifecycles for repairs, rounds, and CAPA.

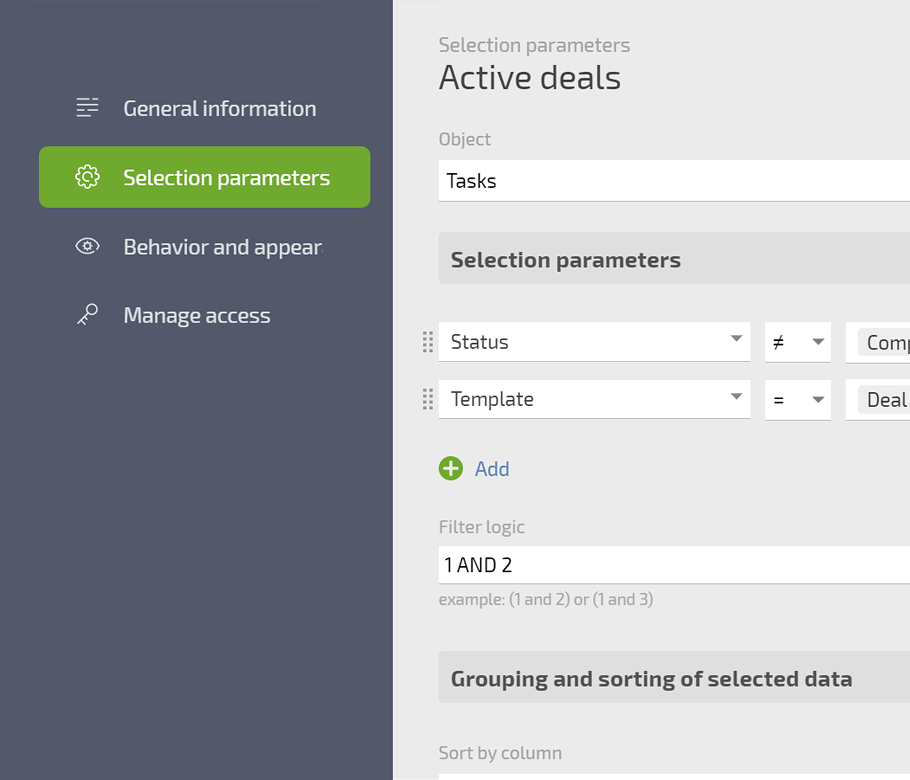

Turn the messy “someone told me something was broken” into a clean, actionable task. Add asset, area, and severity fields and show it on a Planner list called New Maintenance so technicians see a single intake queue.

Let operators track their requests in Client Dashboard. Drag a task from Mechanical Team to Electrical Team in Planner and let conditional lists rewrite assignee and status automatically.

Run a single maintenance inbox for the plant. Every repair, round finding, and CAPA sits in Planfix with an owner, a status, and proof so production and quality see the same data and reports come from structured fields.

Move away from shared inboxes, generic help desks, and ad hoc CAPA spreadsheets. Use plant-specific fields, directories, data tags, and status sets so maintenance, production, and quality work from the same governed workspace.

Use built-in channels, PBX, maps, and storage to keep maintenance data in Planfix.