Control Custom Manufacturing Orders

Planfix turns every custom wood or metal order into one routed, auditable task so your workshop stays predictable, visible, and low cost.

Planfix turns every custom wood or metal order into one routed, auditable task so your workshop stays predictable, visible, and low cost.

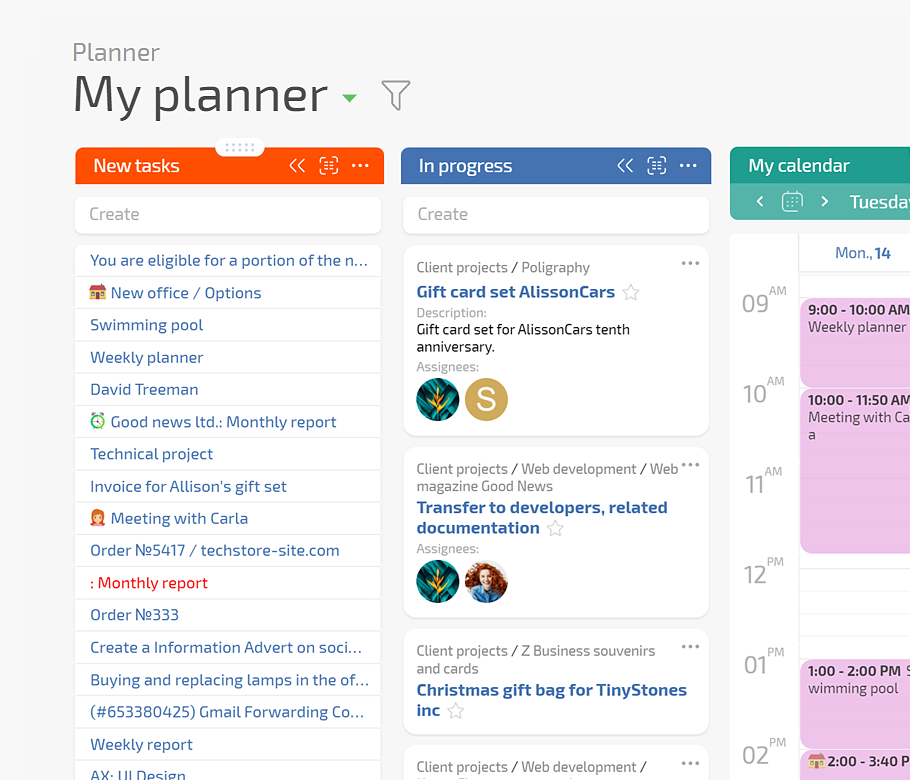

You bring in requests from different channels and keep sketches, drawings, and changes in many places. Planfix lands everything in one workspace, routes it to the right person, and closes the order with proof. Boards in Planner, status sets with transition rules, AI agents, and reports give you real workload visibility.

You work from a single Planner board where office, workshop, and installers see the same order status. Drag a card to the next stage and Planfix rewrites the fields to match. Production sees only its stage, while managers see load, overdue orders, and external operations in reports.

Intake is clean, production sees only ready orders, external operations are visible, and deliveries have proof. Reports show throughput, rework, and margin. You can tell a customer exactly where their order is without calling the foreman.

Boards and status sets are visual, so non-technical staff can drag cards. Planfix works on mobile, so workers attach shop photos on the spot. You can add your own wood and metal attributes as no-code custom fields.

Connect messengers, storage, telephony, and automation tools so intake and updates stay in sync.