Track Rail Maintenance Inspections

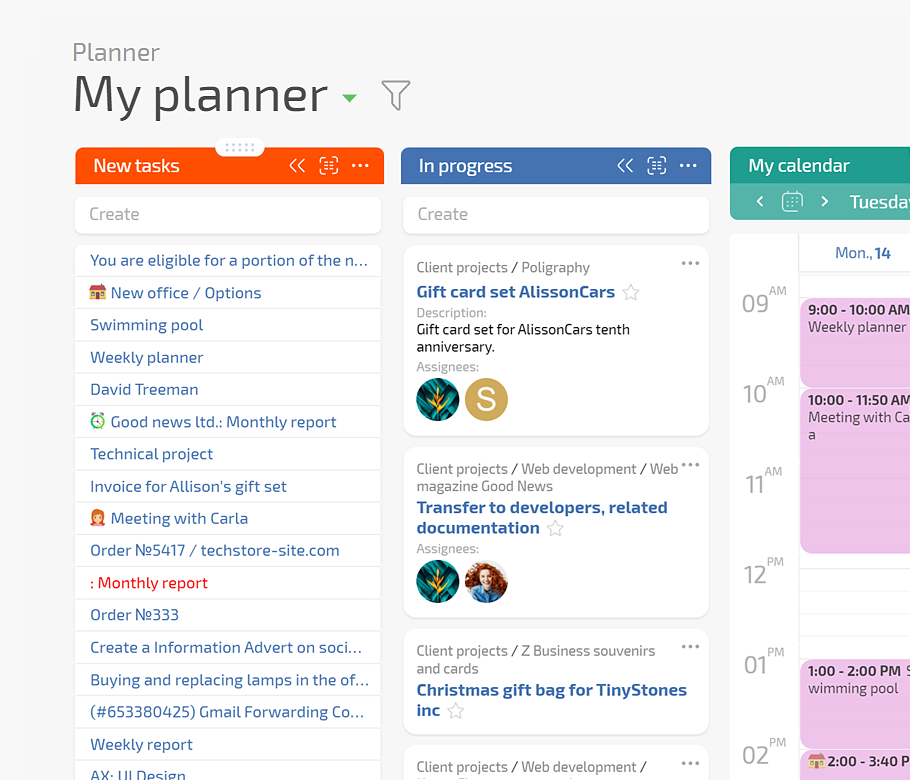

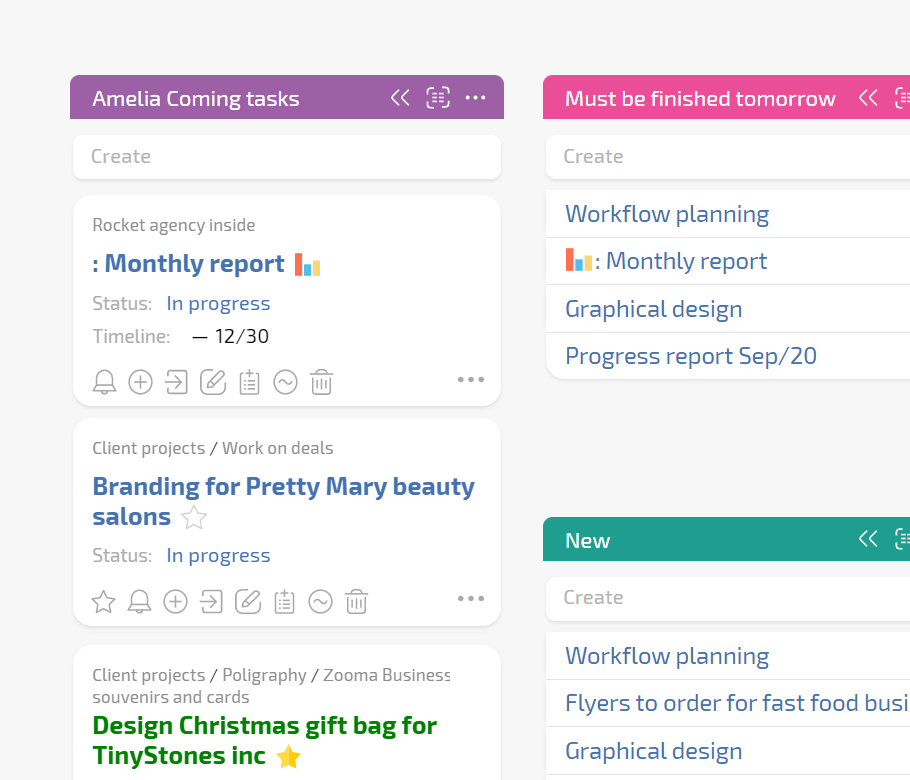

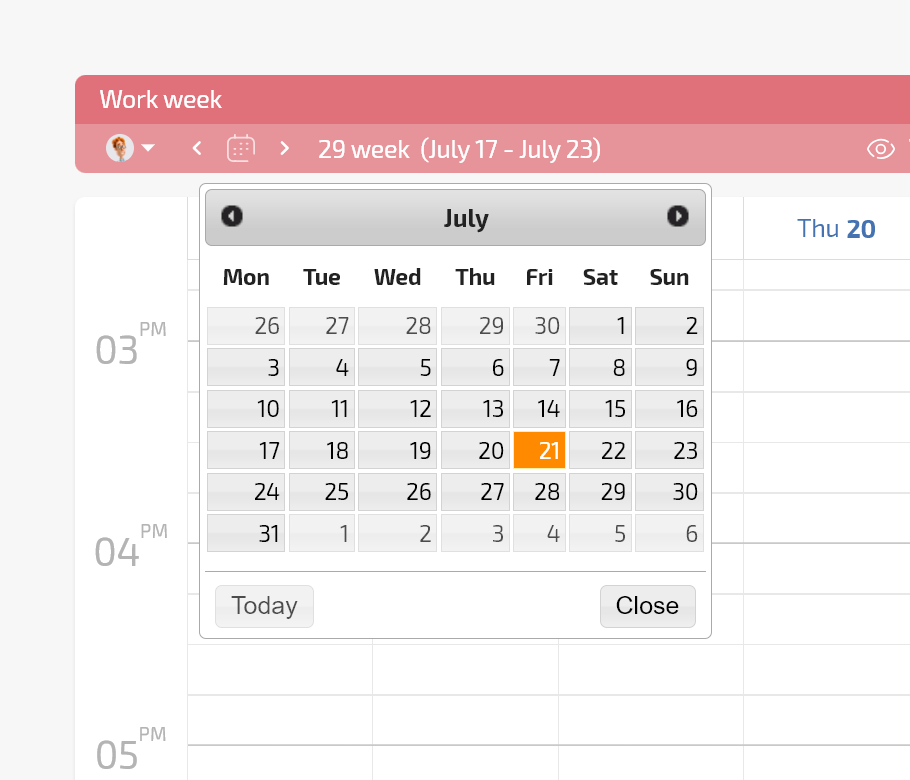

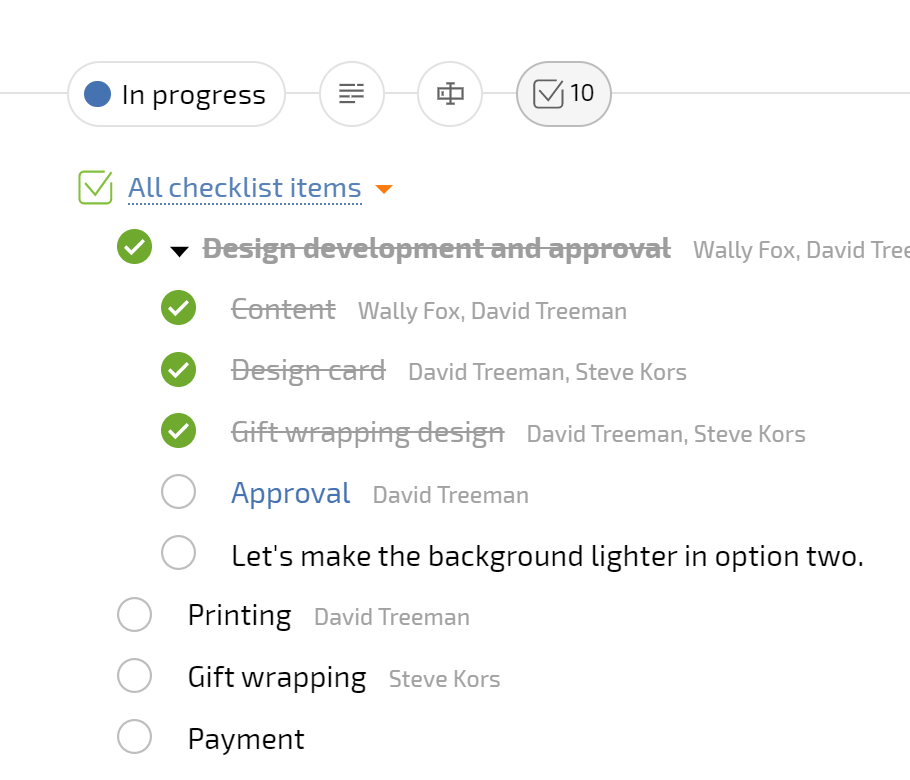

Planfix turns rail track and signaling work orders, inspections, and closeouts into one controlled workflow so you keep assets safe, reduce disruption, and stay audit ready. You plan, execute, and close every job in one system that matches the field.