Handle Plastics Quality Claims

Planfix runs your plastics and composites orders, quality events, and claims in one live system so you ship compliant parts on time, protect margin, and keep key customers.

Planfix runs your plastics and composites orders, quality events, and claims in one live system so you ship compliant parts on time, protect margin, and keep key customers.

You coordinate customer orders, production quality, and complaints across multiple lines and plants. Planfix turns orders, non-conformances, and claims into live tasks in one workspace. Planner boards, quality logs, and claim workflows share the same data from order to audit.

Capture customer orders and revisions in one system with linked drawings, agreements, and full communication history.

Monitor non-conformances, holds, and rework tasks tied to lots, tools, and materials so nothing slips through.

Run complaints and claims through structured investigations, corrective actions, and closures your team and customers can trust.

Begin with claims and complaints to get a quick win. Every complaint becomes a task via email to ticket or channel to task. Rules tag severity, customer, and product family, while Planner shows all open claims in one shared view.

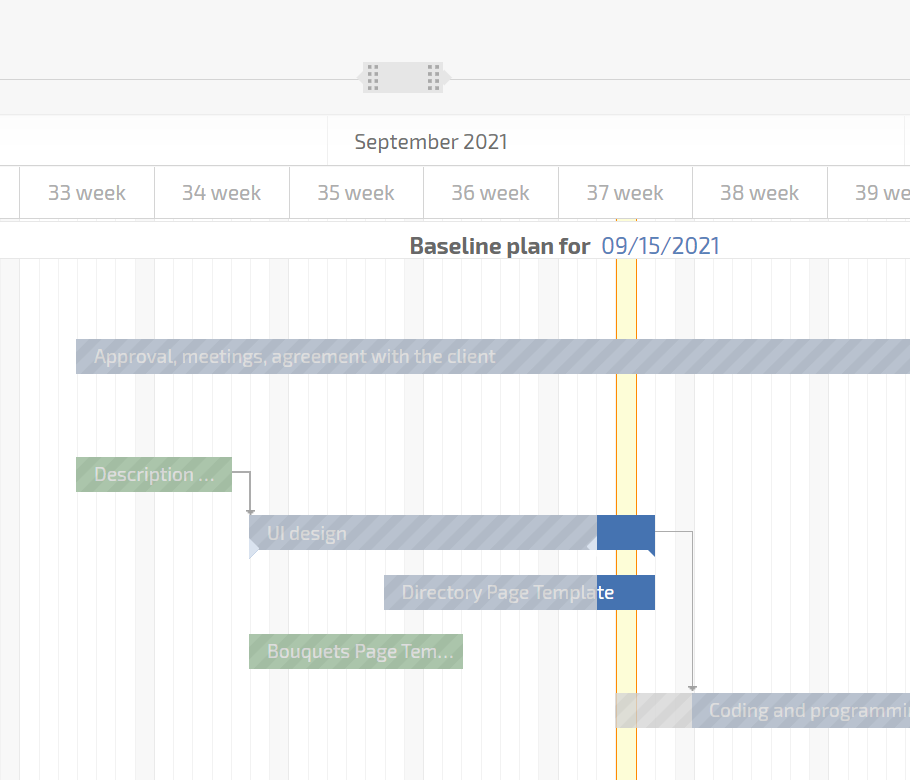

Planfix turns orders, quality events, and complaints into connected task flows. Rules route new work, Planner shows priorities, and data tags capture costs. Whiteboard supports structured investigations, while Client dashboards share live status with customers and managers without manual updates.

ERP, EDI, email, and chats all feed orders, and someone still keeps a private spreadsheet to feel safe.

A late customer claim on Friday triggers frantic chats, calls, and files scattered across drives and inboxes.

You live with the feeling that one missing lot number or attachment could cost you an entire program.

Production and quality teams argue about data and systems instead of seeing one shared process and source of truth.

You walk into customer or certification audits worried that you cannot show a clean trail from complaint to action.

With Planfix, you move from reacting to running a predictable system. Claims follow calm, structured flows. Orders and changes are clear before production starts. Quality data and claim history combine so you fix root causes and stay a reliable supplier.

You spend less time chasing missing details and more time planning stable production and delivery slots.

You walk into customer and certification audits calm, with clear evidence linking complaints, actions, and results.

You discuss pricing, penalties, and renewals knowing your claim, downtime, and cost-of-quality numbers are solid.

Complex order mixes run with fewer last-minute escalations because handovers, changes, and holds are visible early.

Complaints and claims move with clear timelines, responsibilities, and documentation that customers and teams can align around.

Quality and claims data drives improvement projects that protect margin instead of only feeding after-the-fact reports.

Planfix runs alongside ERP and machines, so you can start with claims and quality events without disrupting production. Objects, status sets, and transition rules match each plant or customer flow. Planner, notifications, and AI agents keep updates natural and low-effort.

Connect Planfix with ERP, mail, messaging, telephony, and storage so order, quality, and claim data stays aligned.