Monitor Beverage Production Quality

Planfix runs your beverage shift tasks, quality checks, and returns in one live system. You hit output, protect the brand, and cut complaint costs.

Planfix runs your beverage shift tasks, quality checks, and returns in one live system. You hit output, protect the brand, and cut complaint costs.

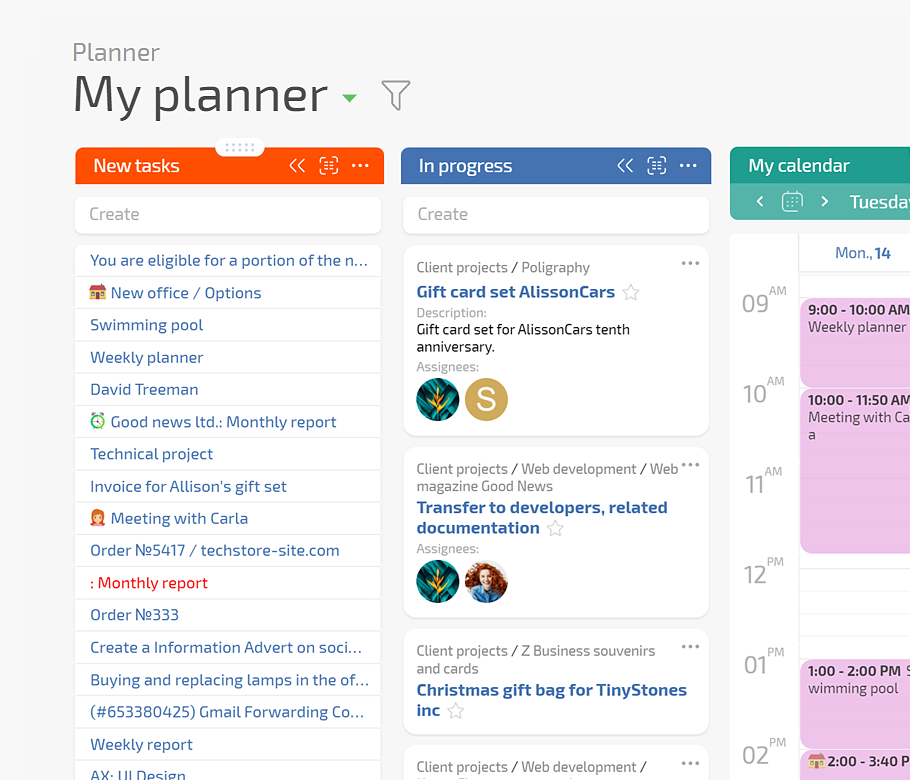

Your job is to keep beverage lines, quality, and returns under control every shift. Planfix gives you one configurable workspace for production, quality, and claims so you see the plan, the issues, and the cost of every decision.

Create a simple Planfix pipeline where every return and complaint lands as a task. Use email to ticket and channel to task so nothing sits in inboxes. Data tags log quantities and credits so you see real loss per SKU.

You start shifts with printouts and chat screenshots, hear about issues from customers before your own team, and feel nervous that something important was missed in the last handover.

You have one live view of production, quality, and returns. Every shift starts from the same plan. Every issue and complaint has an owner and history, and management sees real numbers on downtime, scrap, and claims without ad hoc reports.

You feel calm at shift start because the plan and key risks are visible in one board.

You feel confident when quality managers or regulators ask for evidence because records are complete and organized.

You feel in control of returns and claims instead of dragged by them across calls and chats.

You run every shift from a Planner board that reflects real work instead of manual lists. You protect the brand with complete traceability from production to market returns and reduce scrap, rework, and complaint costs without adding headcount.

Connect lines, labs, and customer channels in one workflow with telephony, email, storage, and calendar connections.