Manage Packaging Manufacturing Quality

You keep packaging and label work moving. Planfix keeps orders, versions, and quality in one place so you ship the right artwork on time and protect your margin.

You keep packaging and label work moving. Planfix keeps orders, versions, and quality in one place so you ship the right artwork on time and protect your margin.

Orders and changes arrive from sales, brand owners, and co-packers all day. Planfix centralizes every order, version, and quality event in one workspace. Requests and complaints become tracked tasks with the right client, SKU, and version already attached.

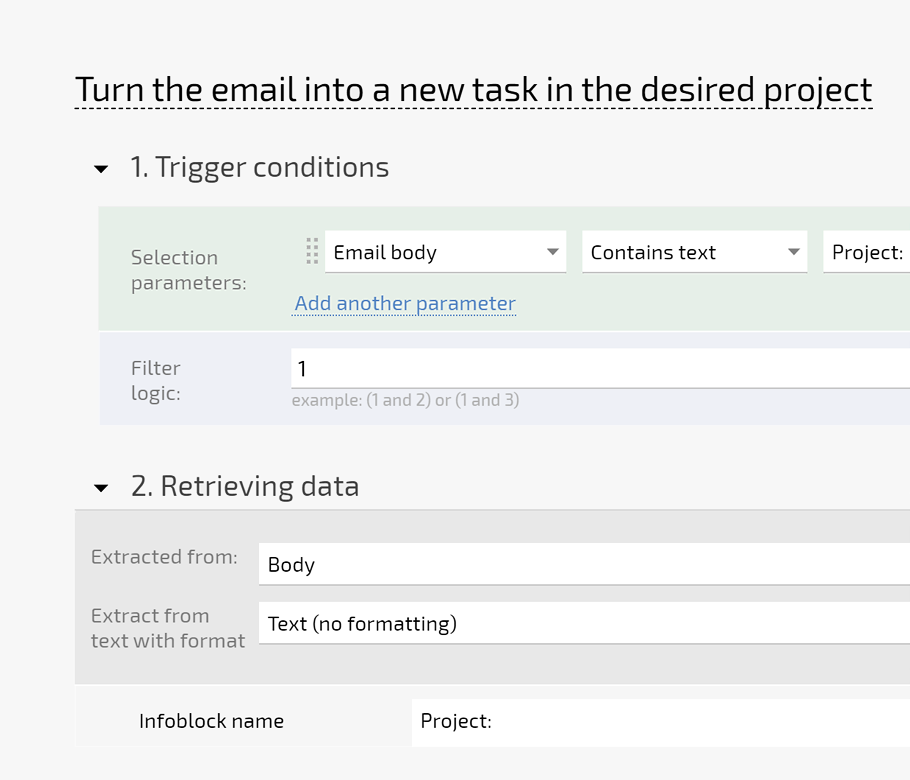

Begin by routing every order and change email into Planfix with a task template. Emails from sales or customer service create tasks with client, SKU, quantity, due date, and status filled. Incomplete orders stand out so nothing unclear reaches production.

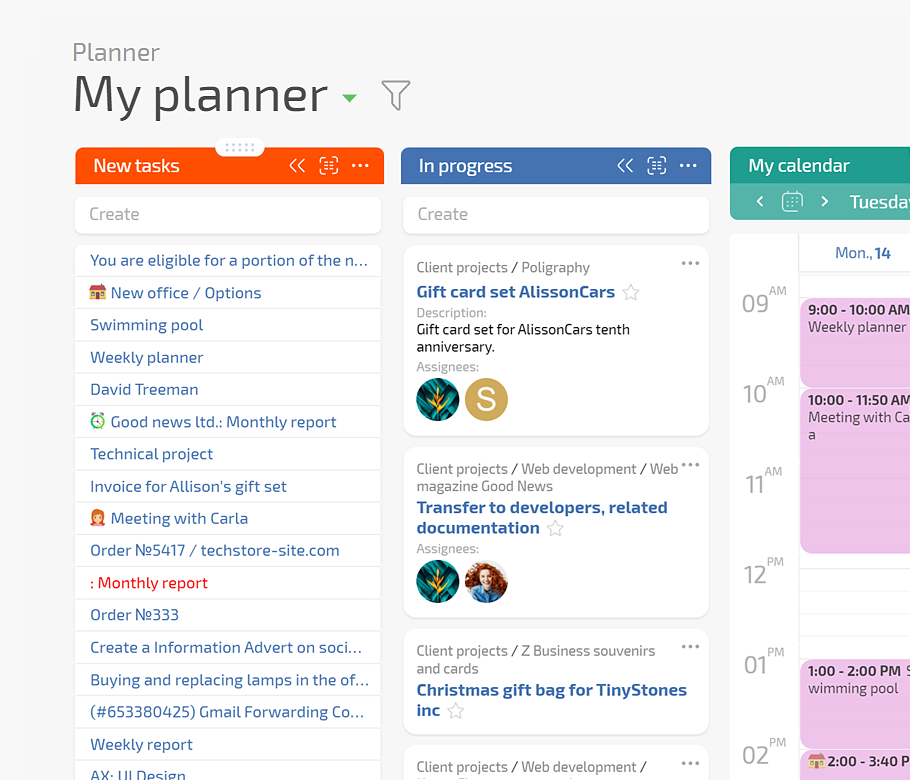

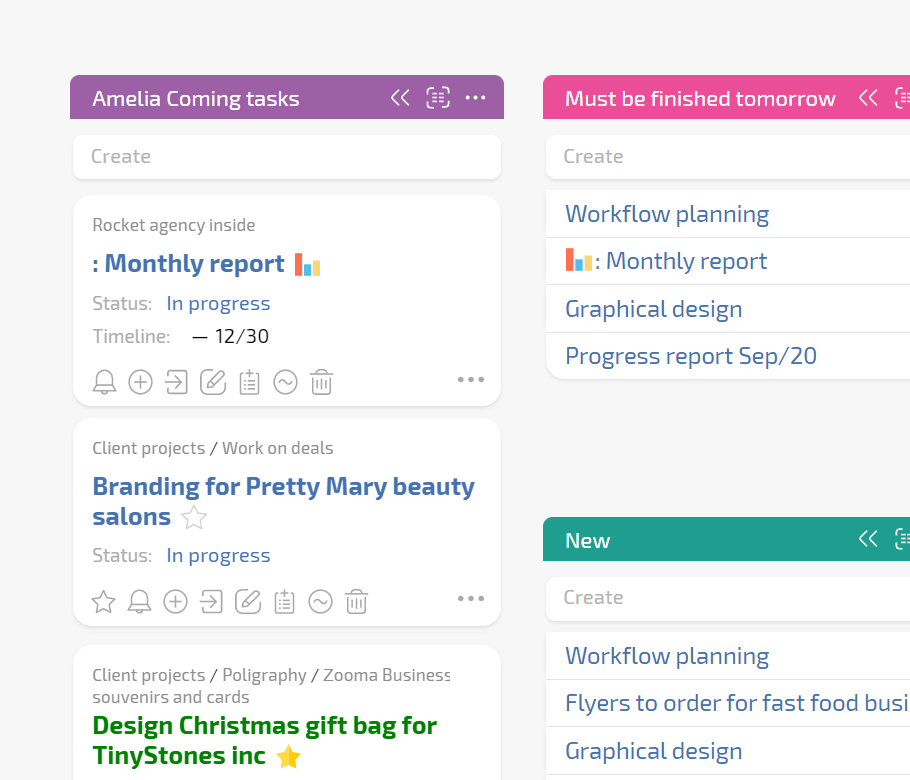

Use Planner to group jobs by press or finishing and watch cards move from brief to shipped. Give key customers a Client Dashboard so they see their orders and proofs in one place and stop repeating status questions.

You move from firefighting to controlled flow. Orders, versions, and quality data stop living in scattered tools. They sit in one system that matches how your plant actually works and supports the way teams already collaborate.

Relief because you know every press is running the right approved version, not a guess based on memory.

Confidence when clients ask for traceability and you can show proof of versions and checks in minutes.

Calm control as changes and claims follow clear workflows instead of improvised, ad hoc conversations in scattered tools.

You start in Planner and see today jobs by press, color coded by due date. You open any card to view client, SKU, artwork version, and approvals. A quality dashboard shows scrap and claims with links back to each job.

You may worry a new system will not match your process or will take months to deploy. Planfix is configurable without code, so you start small, mirror real conversations, and expand only when the team is ready.

Replace shared inboxes, spreadsheets, and generic ticket tools with one configurable system. Email to ticket, Objects, Planner, Data Tags, Project Totals, and Client Dashboards give you one place to run orders, versions, and quality with less chaos and more control.

Connect email, storage, telephony, and automation platforms so orders, proofs, and calls land in the same workflow.